When contemplating the architecture of protection for your vehicle, a carport emerges as a stalwart sentinel, standing guard against the tempestuous whims of Mother Nature. Yet, the strength and resilience of this protective structure hinge significantly on the size of the tube used in its framework. Much like a skeletal structure providing both form and function, the size of the tube not only determines the durability of your carport but also influences its aesthetic appeal. Herein lies an extensive guide that navigates through the labyrinth of tube sizing for carports, illuminating your path toward a structure that harmoniously blends practicality with visual allure.

Understanding the Basics of Tube Sizing

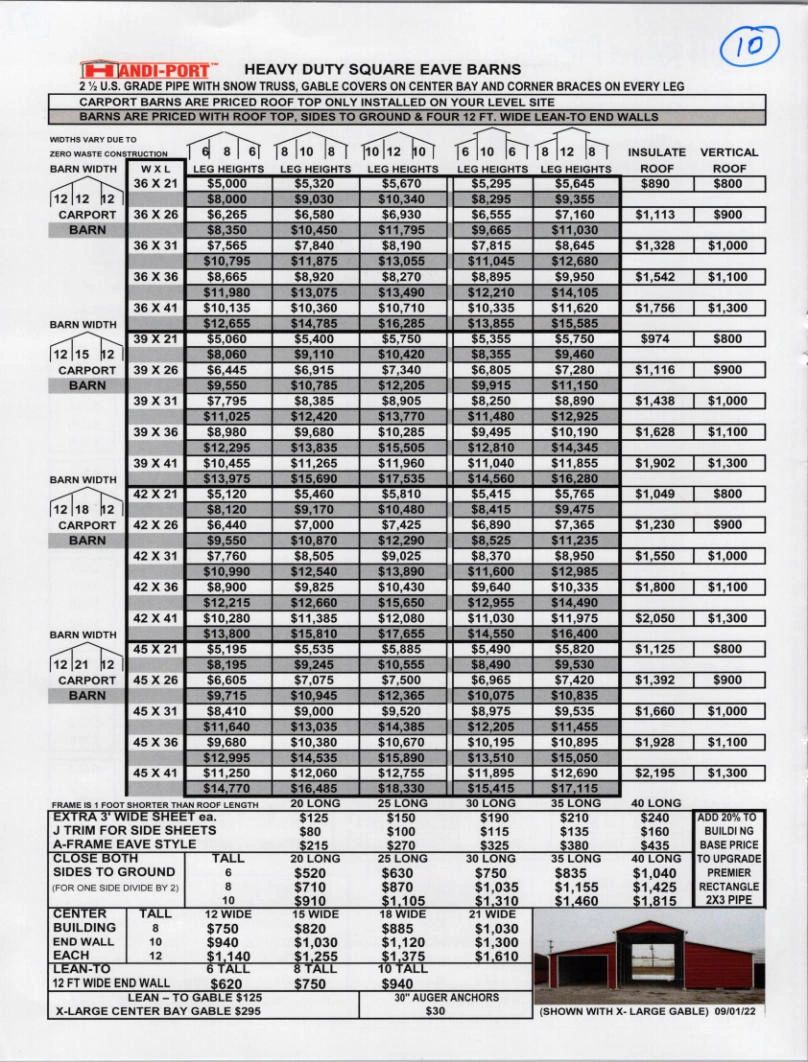

At its core, the tube size refers to the diameter and wall thickness of the steel or aluminum tubing used to construct the carport’s framework. Imagine the tube as the bloodstream of the carport, providing the necessary support and vitality to the structure. The selection of the right tube size is paramount, as it contributes directly to the overall strength, stability, and longevity of your carport. Tubes come in various sizes, typically measured in inches, with common diameters ranging from 1.5 inches to 2.5 inches. Each dimension carries its unique properties, strengths, and weaknesses.

Key Factors Influencing Tube Size

1. Load Capacity: The foremost consideration when selecting the size of the tube is its load capacity. Understanding the weight that your carport will bear is akin to calculating the payload of a cargo ship; you must ensure that it can withstand not only the weight of the vehicle but also potential accumulations of snow, ice, and other environmental factors.

2. Environmental Conditions: Just as the mighty oak bends and sways with the wind, the tube size will respond to environmental conditions. Areas prone to heavy winds, snow, or rain may necessitate larger, thicker tubes to ensure structural integrity during storms or heavy snowfall. Always assess the local climate before determining your tube size.

3. Carport Dimensions: The dimensions of the carport itself play a crucial role. A larger carport will require more substantial tubing to support its frame. Visualize a bridge: the larger the span, the sturdier the supports must be. Thus, calculating the dimensions of the carport and correlating them with appropriate tube sizes is essential.

4. Aesthetic Considerations: Functionality is essential, but aesthetics cannot be overlooked. A carport doesn’t merely serve as a protective shell; it is a statement piece on your property. Thicker tubes impart a sense of robustness, while slimmer profiles offer a more sleek and modern appearance. Let your stylistic preferences inform your choice, blending functionality with visual charm.

Common Tube Sizes for Carports

In the world of carports, tube sizes can significantly vary. The more common options include:

1. 1.5-inch Tubes: Often used in smaller carports, 1.5-inch tubes can provide adequate support for lightweight structures. However, they may fall short in areas with heavy snowfall or wind gusts. Picture them as the featherweight contender in a boxing match, agile yet potentially vulnerable.

2. 2-inch Tubes: A middle-weight option, 2-inch tubes offer a balance between weight capacity and versatility. They’re suitable for average car sizes and moderate environmental conditions. Think of them as the dependable sedan—reliable and functional without being ostentatious.

3. 2.5-inch Tubes: For larger carports or regions susceptible to extreme climates, 2.5-inch tubes present a robust solution. They are like the heavyweight champions of tube sizing—solid, stable, and formidable against the elements. Their enhanced thickness contributes to an impressive load capacity, ensuring your vehicle remains shielded, come rain or shine.

Choosing the Right Material

While tube size is a crucial element, the choice of material deserves attention too. Steel and aluminum dominate the landscape, each offering distinct advantages. Steel tubes, with their unparalleled strength, can withstand greater forces but are prone to rust without proper treatment. Conversely, aluminum, often lauded for its lightweight and corrosion-resistant properties, presents an appealing option for DIY enthusiasts seeking simplicity in installation. Choose wisely, for the foundation of your carport rests upon these decisions.

Installation and Structural Considerations

After determining the size and material of the tubes, installation comes next. Proper alignment and secure anchoring are vital. Envision the process as assembling the pieces of a grand puzzle, each tube fitting together to form a cohesive sanctuary for your vehicle. A well-executed installation ensures maximum stability and longevity of your carport.

Conclusion

In summation, the choice of tube size for carports embodies more than mere numbers; it is an interplay of strength, aesthetic helix, and environmental resilience. Just as a painter selects his brush with care to create a masterpiece, one must thoughtfully consider each aspect of tube sizing to achieve an optimal fusion of beauty and functionality. The next time the elements threaten to overshadow your prized automobile, may you stand confident, knowing that your carport was constructed with precision and foresight. Embrace the journey of creation and protection with the right tube size by your side.

Leave a Comment