The world of machining is akin to an intricate symphony where each component plays its unique note, culminating in a harmonious masterpiece. Among these components, drill bits and taps synergize to create threads that bind mechanical components seamlessly. When engaging with a 3/8 tap, the intricacies of selecting the right drill bit size become paramount, unveiling a captivating interplay between precision and engineering prowess.

In this guide, we will traverse the fascinating realm of drill bit sizes for a 3/8 tap, delving into elements that dictate selection, the relationship between tap and drill, and the significance of understanding the nuances that govern their compatibility.

To embark on this journey, let us first unravel the mysteries of tap designation. A 3/8 tap refers to the nominal diameter size of the external thread it creates, which measures 0.375 inches. Yet, this figure is merely the portal to a realm of deeper understanding regarding tap types, thread pitches, and, ultimately, the requisite drill bit size.

The Importance of Drill Size

Choosing the appropriate drill bit size is akin to selecting the perfect paintbrush for a masterpiece. The size of the drill bit directly influences the quality of the thread—too small a bit can lead to interference, while too large a one may yield insufficient material for the threads to grip onto securely.

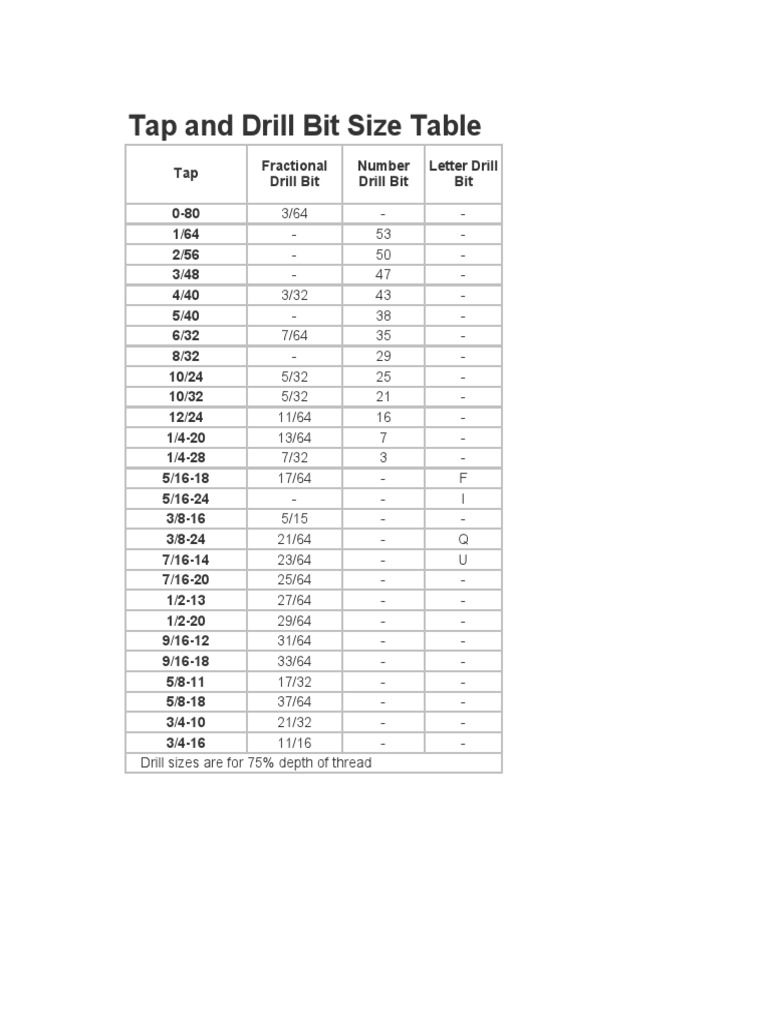

For a 3/8 tap, the standard drill bit size commonly recommended is a 21/64 inch bit. This size provides sufficient clearance for the tap and ensures that the threads will engage properly with the surrounding material, enabling a seamless union akin to a well-tuned instrument resonating harmoniously.

Understanding Thread Pitch

Thread pitch is another critical aspect to consider, acting as the rhythm of our symphonic performance. For 3/8 taps, there are primarily two threads to explore: the coarse thread (16 threads per inch, TPI) and the fine thread (24 TPI). The choice of pitch alters the drilling approach significantly. Coarse threads require a less snug fit, thus occasionally accommodating a slightly larger drill bit size, whereas fine threads demand precision that necessitates strict adherence to the prescribed drill bit dimension.

When utilizing a coarse 3/8 tap, enthusiasts might consider a drill bit size of 5/16 inches or the 21/64 inch bit previously mentioned, ensuring that the tapped thread engages robustly. In contrast, the fine 3/8 tap demands meticulous attention, where the standard 21/64 inch drill bit proves optimal.

Material Matters

The selection of drill bit size also envelops the type of material being worked on—a factor analogous to the canvas upon which an artist paints. Material density affects the cutting efficiency and the final finish of the thread. For softer materials such as aluminum, the 21/64 inch drill bit works efficiently, cutting through with remarkable ease.

However, in more robust materials like stainless steel, the stakes are elevated. Here, opting for a cobalt or high-speed steel drill bit not only preserves the integrity of the tool but also ensures clean, precise holes that form the perfect foundation for the threads. The uniqueness of the material being drilled can necessitate minor adjustments—truths that every seasoned craftsman learns in their pursuit of perfection.

Exploring Alternative Drill Bit Sizes

Although the 21/64 inch drill bit often reigns supreme in popularity, creative alchemists of the workshop sometimes venture into the territory of alternative sizes for specialized needs or scenarios. A size 3/8 inch bit may be contemplated but typically overshoots the target, leading to a loose-thread scenario. Emphasizing the art of precision, such variants can serve niche applications where creativity intertwines with the mechanical.

Threading Techniques

As we delve deeper into the intricacies of threading techniques, it becomes crucial to embrace methods that elevate a simple 3/8 tap operation into an exquisite art form. Utilizing cutting fluid during drilling can reduce friction and heat, preserving both the drill bit and the tap’s integrity—similar to how an artist maintains their brush strokes with the right palette. Additionally, tapping in a steady, controlled manner fosters a profound sense of mastery over the creation process.

The Final Cut

What emerges when one pairs the correct drill bit size with a 3/8 tap is nothing short of a testament to the harmonious relationship between machinery and artistry. The precision invoked in each selection serves not only to create functional threads but to elevate the experience into an enthralling endeavor worthy of the finest artisans. Just as a captivating symphony unfolds, the union of drill, tap, and material leads to a delightful dance that defies the ordinary.

In summation, whether you are embarking on a simple DIY project or engaging in heavy-duty manufacturing, understanding the essentials of drill bit sizing for a 3/8 tap can significantly affect the outcome. The meticulous selection and application of each tool allow craftsmen to create strong, reliable threads that echo through the ages, resonating with the impeccable notes of quality and craftsmanship. Equip yourself with this knowledge, and let your journey through the marvels of threading and machinery flourish.

Leave a Comment