Hydraulic gear motors are integral components in various machinery and equipment, converting hydraulic energy into mechanical power with remarkable efficiency. One important aspect that often garners considerable attention from engineers and industry specialists is the hydraulic gear motor efficiency curve. This graphical representation illustrates a motor’s efficiency across different operational conditions, becoming an essential tool for understanding performance dynamics in hydraulic systems. This article delves into the intricacies of the hydraulic gear motor efficiency curve, exploring its importance, the factors that influence it, and practical implications for design and operation.

Understanding the Hydraulic Gear Motor Efficiency Curve

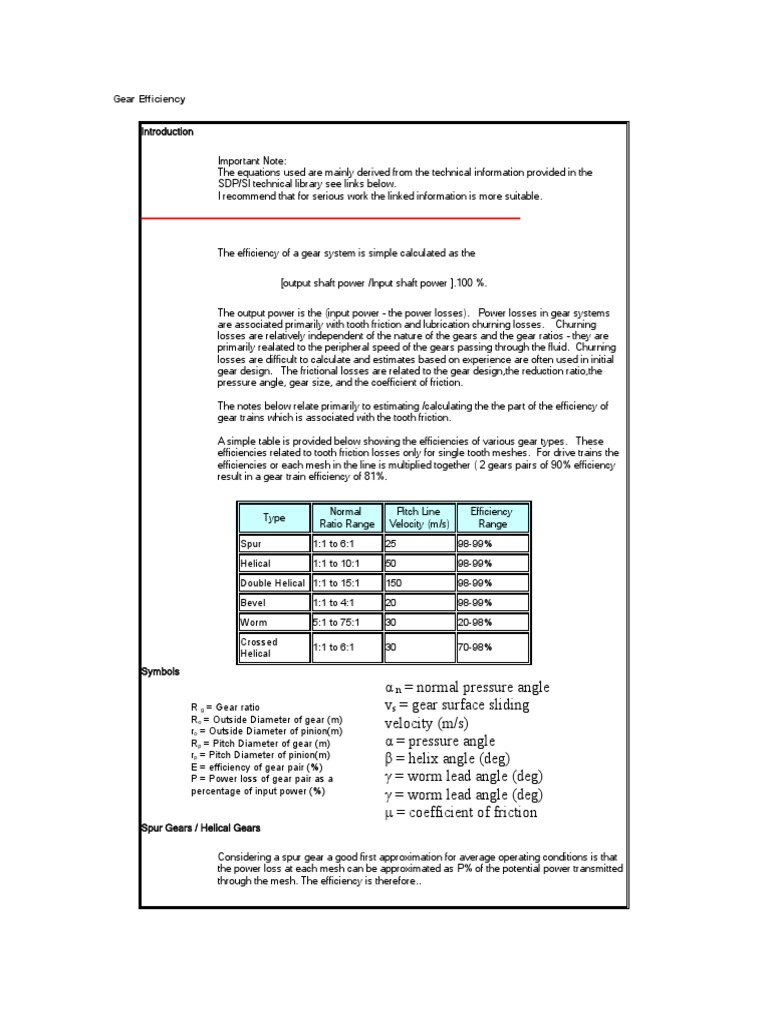

The hydraulic gear motor efficiency curve is a complex plot that delineates the relationship between efficiency and various parameters such as flow rate, pressure, and speed. Efficiency, in this context, is defined as the ratio of useful output power to the total input power. Typically, these curves exhibit particular shapes, often peaking at certain flow rates and declining beyond these optimal conditions. This characteristic phenomenon is pivotal; it signifies that while a motor can operate under a continuum of conditions, its performance varies significantly across different scenarios.

Key Factors Influencing the Efficiency Curve

The efficiency of hydraulic gear motors is influenced by several interconnected factors:

- Viscosity of Hydraulic Fluid: The viscosity of the hydraulic fluid plays a critical role in determining the losses due to friction and turbulence within the motor. Higher viscosity fluids may enhance volumetric efficiency at low speeds but can lead to significant losses at elevated speeds, thereby distorting the overall efficiency curve.

- Pressure Levels: The efficiency curve also shifts with varying hydraulic pressures. With moderate pressures, the motor often operates within an optimal range, but excessive pressure can lead to detrimental losses due to internal leakage and heating. This aspect necessitates careful consideration when defining operating parameters.

- Design Characteristics: The physical design of the motor, including gear tooth geometry, materials, and manufacturing tolerances, can markedly influence the efficiency. Precision-engineered components minimize backlash and improve meshing, thus enhancing the shape and peak of the efficiency curve.

- Speed of Operation: The interaction between speed and efficiency forms a crucial part of the efficiency curve. As speed increases, hydraulic losses tend to rise due to increased fluid shear, resulting in a decline in overall efficiency after a particular optimal point.

Interpreting the Curve

Examining the hydraulic gear motor efficiency curve provides valuable insights into performance optimization. Engineers and technicians need to ascertain the peak efficiency point—the sweet spot where the motor performs most effectively. This point serves as a guiding metric for system design and operational protocols. Operating at or near this sweet spot minimizes wasted energy and maximizes productive output, creating a balanced harmony between power consumption and mechanical work.

Moreover, understanding the root causes of efficiency loss beyond the peak is equally significant. Engineers often encounter scenarios where operating conditions shift outside of the preferred range. Awareness of how these shifts influence the efficiency curve enables the development of strategic interventions—such as implementing variable speed drives or optimizing hydraulic circuits—to maintain performance integrity even under fluctuating conditions.

Practical Implications of Efficiency Curves

Understanding the efficiency curve has tangible implications in various industrial applications. In hydraulic systems, particularly those utilized in heavy machinery and manufacturing processes, the impact of efficiency on operational costs cannot be overstated. Higher efficiency translates to lower fuel consumption or energy use, tremendously affecting the bottom line.

In applications such as mobile equipment, where hydraulic motors drive pivotal components like lifts, loaders, and excavators, maximizing efficiency directly correlates to enhanced performance and reliability. Equipment operators who grasp the significance of the efficiency curve can make informed decisions, optimizing operating conditions and prolonging machinery lifespan.

Innovation and Future Trends

The future of hydraulic gear motor design is moving toward enhanced compatibility with renewable energy sources, making efficiency curves even more relevant as we transition to a sustainable energy paradigm. As these motors evolve, their efficiency curves will become essential indicators of performance, guiding both design and operational strategies.

Conclusion

The hydraulic gear motor efficiency curve is not merely a technical detail; it embodies a wealth of information about the delicate interplay between performance metrics in hydraulic systems. By comprehensively understanding the factors that influence this curve, industry professionals can optimize their systems for maximum efficiency and productivity. The emergence of new technologies promises to further shape these curves, leading to a future where hydraulic systems not only meet but exceed the demands of modern applications. Mastery of the efficiency curve is thus not just advantageous; it is indispensable in the quest for peak performance in hydraulic machinery.

Leave a Comment